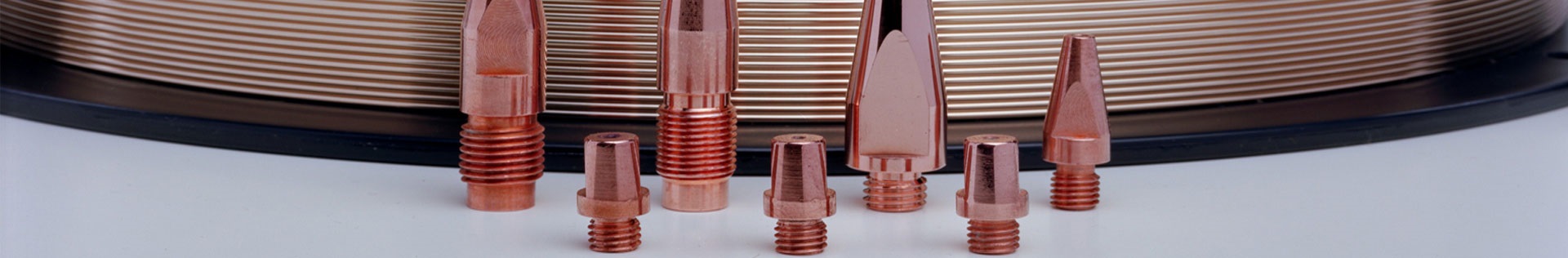

Contact Tips

Welding contact tips for the most demanding applications

For demanding applications requiring high wear characteristics and resistance to softening, Luvata has developed a line of dispersion strengthened copper tips that offer a number of advantages:

- improved uptime due to better weld quality

- increase productivity due to predictable contact tip changeovers

- lower labor and material costs as a result of less rework

- reduce costs with lower inventory levels

Alloys

- Copper Chrome Zirconium (CuCrZr)

- Deoxidized Phosphorus Copper (DHP)

- Dispersion Strengthened Copper (DSC)

Dispersion Strengthened Copper (DSC) contact tips

In controlled applications our DSC tips have provided up to 5X the life of a standard DHP contact tip.

For many years, deoxidized phosphorus copper (DHP) was the preferred alloy for contact tips because of its low cost and availability - it is still in widespread use today. However, for more demanding applications requiring high wear characteristics and resistance to softening, other alloys can give a superior performance and are better suited for the most rigorous arc welding conditions.

Dispersion strengthened copper (DSC) tips are unsurpassed in quality and reliability. DSC tips will maintain their hardness at the highest temperatures and are extremely durable.