CuZr, CuCr1Zr and CuNiSi Products

Expertise comes from dedicated processes and strong process knowhow

Luvata's CuZr, CuCr1Zr and CuNiSi products can be tailor made to customer needs. Our flexible manufacturing operations and unique tool room allow a large selection of sizes and shapes to be made from all these alloys. We are constantly expanding our offering of CuZr, CuCr1Zr and CuNiSi alloys according to customers more demanding applications. We can offer any quantity from test patches to large scale requirements.

Alloyed copper products are tailor made for customer needs

Luvata’s CuZr (C15000), CuCr1Zr (C18150) and CuNiSi products can be tailor made to customer needs. CuNiSi alloys are a group of different compositions that match with for example these standard alloys: C18000, C70260, CW111C. Our flexible manufacturing operations and unique tool room allow a large selection of sizes and shapes to be made from all these alloys. All these alloys are excellent for hot forming and in some cases further cold working can be used to improve mechanical properties. Read more about our customized copper alloy products.

Multiple application opportunities in various industries

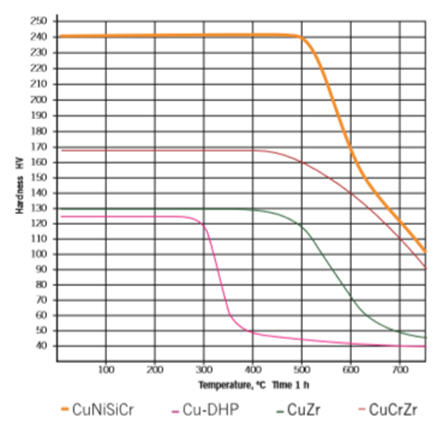

These copper alloys are precipitation hardening alloys that have their unique properties made by aging heat treatment. Combination of high temperature hardness and high conductivity is typically needed in welding applications and electrical motor and generator components for the most demanding applications. Good mechanical properties and good thermal conductivity make these alloys suitable for different water-cooled components, such as structural cooling elements and casting and extrusion molds. Aged temper offers also high fatigue resistance and durability for wear and corrosion.

Our focus is in continuous development

- electrical motors and generators

- casting moulds

- welding materials

- commutators

- other applications where high conductivity and good resistance to softening are needed

High temperature alloys are manufactured with many different processes. They are available in various shapes and sizes.

| Cast billets | ∅ 210 mm, ∅ 278 mm & 730 x 180 mm |

| Round rods | Ø 3 - 160 mm |

| Wires | Ø 2 - 25 mm |

| Hexagon and square rods | 8 - 32 mm |

| Other products e.g. flat shapes | by request |

Different tempers are made with varying the amount of cold work. Please consult Luvata for best option.

| Alloy | EN | ASTM | Hardness | Electrical Conductivity | Tensile strength | Elongation | ||

| HV | HB | MS/m | %IACS | N/mm2 | A5 % | |||

| CuZr | CuZr/CW120C | C15000 | 115-140 | 116-140 | min 52 | 85-92 | 350-430 | 10-25 |

| CuCrZr | CuCrZr/CW106C | C18150 | 120-170 | 120-160 | min 44 | 75-90 | 460-560 | 10-20 |

| CuNiSi | CuNiSi/CW111C | C70260 | 130-240 | 130-222 | min 22 | 38-51 | 420-780 | 9-16 |

| CuNiSiCr | CuNiSiCr/CW111C | C18000 | 220-250 | 208-240 | min 22 | 38-51 | 650-800 | 9-15 |

| CuNiSiCrZr | 180-220 | 172-208 | min 22 | 38-51 | 650-800 | > 5 | ||

Softening behaviour – resistance against softening